Introduction to 20mm Coarse Aggregate Sieve Analysis

Sieve analysis is a critical quality control test in civil engineering used to determine the particle size distribution of coarse aggregates. For 20mm coarse aggregates, which are widely used in structural concrete, this analysis ensures the material meets the required specifications for various construction applications.

20mm coarse aggregate, also known as "single-sized aggregate" according to IS:383-2016, is characterized by a nominal maximum size of 20mm. The sieve analysis helps engineers and quality control personnel verify that the gradation of the aggregate is suitable for the intended application, whether for structural elements, pavements, or other concrete structures.

20mm coarse aggregate is one of the most commonly used sizes in concrete construction. According to IS:383-2016, it is classified as "single-sized aggregate" and has well-defined gradation requirements that must be strictly adhered to for quality concrete production.

IS:383-2016 Specifications

The Bureau of Indian Standards (BIS) provides specific gradation requirements for 20mm single-sized aggregates through IS:383-2016. These specifications ensure the aggregate has the proper size distribution for optimal performance in concrete and other construction applications.

| IS Sieve Size (mm) | Percentage Passing by Weight | Specification Limits |

|---|---|---|

| 25.0 | 100 | 100 |

| 20.0 | 85-100 | 85-100 |

| 10.0 | 0-20 | 0-20 |

| 4.75 | 0-5 | 0-5 |

Using aggregates that don't meet the IS:383-2016 specifications may result in concrete with reduced workability, lower strength, and potential durability issues. Always verify your 20mm aggregate meets these standards before use in structural applications.

Comparing 10mm and 20mm Aggregates

Understanding the differences between 10mm and 20mm aggregates is important for selecting the right material for specific construction applications.

| Characteristic | 10mm Aggregate | 20mm Aggregate |

|---|---|---|

| Surface Area | Higher surface area per unit volume | Lower surface area per unit volume |

| Water Requirement | Requires more water for same workability | Requires less water for same workability |

| Cement Requirement | Needs more cement paste for coating | Needs less cement paste for coating |

| Suitable Applications | Thin sections, architectural concrete, repairs | Structural members, foundations, large volume concrete |

| Workability | Better flowability in confined spaces | More economical for bulk concrete |

| Strength Development | Slightly higher early strength | Good long-term strength, more economical |

| Fineness Modulus Range | 5.5 - 7.0 | 6.0 - 8.0 |

The choice between 10mm and 20mm aggregate should be based on specific project requirements. Use 20mm for economical bulk concrete and structural elements. Choose 10mm for thin sections, congested reinforcement areas, and where superior finish is required.

Required Equipment

Before beginning the sieve analysis procedure for 20mm aggregate, ensure you have the following equipment ready:

Balance

A precision balance with accuracy of at least 0.1g and capacity of at least 10kg for weighing samples.

IS Test Sieves

Standard test sieves of sizes 40mm, 25mm, 20mm, 10mm, 4.75mm, 2.36mm, and pan.

Mechanical Sieve Shaker

For consistent agitation of sieves (recommended for 20mm aggregate due to larger sample size).

Oven

For drying samples at 110±5°C to constant weight.

Containers & Tools

Large trays, brushes, and sturdy containers for handling the coarse aggregate.

Sampling Equipment

Quartering equipment, riffles, or sample splitters for obtaining representative samples.

For 20mm aggregate, the minimum sample size should be 5kg according to IS:2386 (Part I). Using a larger sample provides more representative results, especially for non-uniformly graded materials.

Step-by-Step Procedure

Follow these detailed steps to conduct a proper sieve analysis for 20mm coarse aggregates:

-

Sample Collection

Collect a representative sample from the aggregate stockpile following proper sampling techniques according to IS:2430. For 20mm aggregate, the sample should be collected from different locations and depths in the stockpile to ensure representativeness.

-

Sample Reduction

Reduce the sample to laboratory test size (minimum 5kg for 20mm aggregate) using quartering method or sample splitters. Ensure the reduced sample represents the original material accurately.

-

Sample Preparation

Clean the sample to remove dust and foreign materials. If the aggregate has excessive dust or moisture, wash the sample and dry it in an oven at 110±5°C until it reaches a constant weight (typically 24 hours for 20mm aggregate).

-

Weighing the Sample

Accurately weigh the prepared dry sample and record this as the total sample weight (W). For 20mm aggregate, the sample weight should typically be between 5-8kg for accurate results.

-

Sieve Selection & Arrangement

Select the appropriate sieves for 20mm aggregate analysis: 40mm, 25mm, 20mm, 10mm, 4.75mm, 2.36mm and a pan at the bottom. Arrange the sieves in descending order of aperture size (largest at the top).

-

Sieving Procedure

Pour the weighed sample onto the top sieve. For 20mm aggregate, consider dividing the sample into smaller portions if necessary to avoid overloading the sieves. Place the stack of sieves in the mechanical shaker and secure properly. Run the shaker for 10-15 minutes. If using manual sieving, shake with horizontal and vertical motions for at least 5 minutes per sieve for 20mm aggregate.

-

Material Collection & Weighing

Carefully remove each sieve from the stack. Weigh the material retained on each sieve to the nearest 0.1g. For 20mm aggregate, ensure larger particles don't get jammed in the sieve openings. Check sieves with a brush to ensure all particles are removed. Record these weights in a tabular format.

-

Calculations

Calculate the following for each sieve:

- Weight retained

- Percentage retained = (Weight retained / Total weight) × 100

- Cumulative percentage retained

- Percentage passing = 100 - Cumulative percentage retained -

Fineness Modulus Calculation

Calculate the fineness modulus by adding the cumulative percentage retained on standard sieves (80mm, 40mm, 20mm, 10mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm) and dividing the sum by 100. For 20mm aggregate, this typically ranges from 6.0 to 8.0.

-

Gradation Curve

Plot a gradation curve (semi-log graph) with sieve size on the x-axis (logarithmic scale) and percentage passing on the y-axis. For 20mm aggregate, compare this curve with the IS:383-2016 specifications to evaluate compliance.

-

Compliance Check

Compare the percentage passing values with the IS:383-2016 requirements for 20mm single-sized aggregate. The material should have 100% passing 25mm sieve, 85-100% passing 20mm sieve, 0-20% passing 10mm sieve, and 0-5% passing 4.75mm sieve.

Sample Calculation

Let's go through a complete sample calculation for 20mm aggregate sieve analysis:

Sample Data

Total sample weight = 5000g

| Sieve Size (mm) | Weight Retained (g) | % Retained | Cumulative % Retained | % Passing |

|---|---|---|---|---|

| 40.0 | 0 | 0.00 | 0.00 | 100.00 |

| 25.0 | 0 | 0.00 | 0.00 | 100.00 |

| 20.0 | 750 | 15.00 | 15.00 | 85.00 |

| 10.0 | 3250 | 65.00 | 80.00 | 20.00 |

| 4.75 | 750 | 15.00 | 95.00 | 5.00 |

| 2.36 | 200 | 4.00 | 99.00 | 1.00 |

| Pan | 50 | 1.00 | 100.00 | 0.00 |

| Total | 5000 | 100.00 | - | - |

Calculation Steps:

-

Calculate % Retained for each sieve

% Retained = (Weight retained / Total weight) × 100

Example for 20mm sieve: % Retained = (750g / 5000g) × 100 = 15.00% -

Calculate Cumulative % Retained

Cumulative % Retained = Sum of % retained up to that sieve

Example for 10mm sieve: Cumulative % Retained = 0 + 0 + 15.00 + 65.00 = 80.00% -

Calculate % Passing

% Passing = 100 - Cumulative % Retained

Example for 10mm sieve: % Passing = 100 - 80.00 = 20.00% -

Calculate Fineness Modulus

Fineness Modulus = (Sum of cumulative % retained on standard sieves) / 100

For this example, considering standard sieves:

FM = (0 + 0 + 0 + 15.00 + 80.00 + 95.00 + 99.00 + 100 + 100 + 100) / 100 = 5.89

Compliance Check

| Sieve Size (mm) | Sample % Passing | IS:383-2016 Requirement | Status |

|---|---|---|---|

| 25.0 | 100.00 | 100 | ✓ PASS |

| 20.0 | 85.00 | 85-100 | ✓ PASS |

| 10.0 | 20.00 | 0-20 | ✓ PASS |

| 4.75 | 5.00 | 0-5 | ✓ PASS |

The 20mm aggregate sample meets all IS:383-2016 specifications. The fineness modulus is 5.89, which is slightly below the typical range for 20mm coarse aggregates (6.0-8.0). This indicates that the sample contains slightly more finer particles than typical 20mm aggregate.

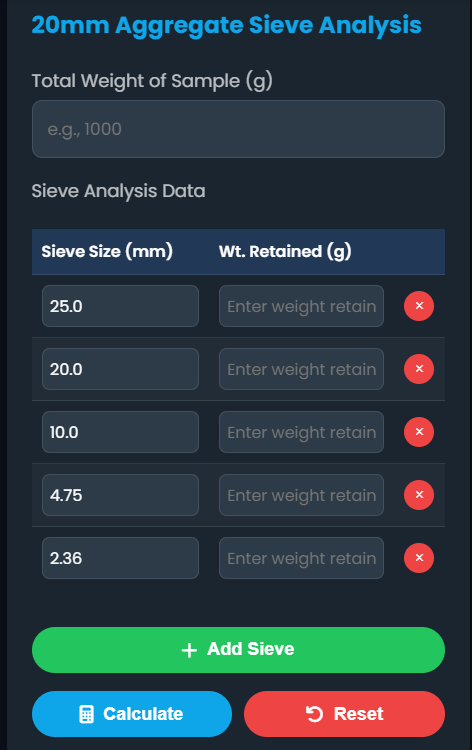

Using the 20mm Sieve Analysis Calculator

Our 20mm Sieve Analysis Calculator automates the entire process, providing instant calculations, compliance checks, and visual representations of your aggregate gradation.

20mm Sieve Analysis Calculator

The calculator makes sieve analysis simple and error-free through these features:

-

Intuitive Data Entry

The calculator provides pre-populated fields with standard sieve sizes for 20mm aggregate (40mm, 25mm, 20mm, 10mm, 4.75mm, 2.36mm). You simply enter the total sample weight and the weight retained on each sieve.

-

Automatic Calculations

Once you input your data and click "Calculate," the calculator automatically:

- Computes percentages retained and cumulative percentages

- Calculates percentage passing for each sieve

- Determines material in the pan (passing the smallest sieve)

- Calculates the fineness modulus -

Visual Representation

The calculator generates a logarithmic particle size distribution graph that plots the percentage passing against sieve size. This visual representation makes it easy to see if your aggregate falls within specification limits.

-

IS:383-2016 Compliance Check

The calculator automatically checks if your 20mm aggregate meets IS:383-2016 requirements by comparing the percentage passing values with standard specifications. It highlights any deviations from the requirements.

-

Comprehensive PDF Reports

Generate detailed PDF reports of your sieve analysis results including:

- Complete tabular data with calculations

- Particle size distribution curve

- Comparison with IS:383-2016 specifications

- Fineness modulus with interpretation

- Overall compliance assessment

The calculator handles fineness modulus calculation correctly by considering all standard sieves in the series, even those not tested. For sieves not tested but in the standard series, it uses interpolation on a logarithmic scale to estimate cumulative retention percentages.

Interpreting Results & Common Issues

Understanding your sieve analysis results is crucial for proper material selection and quality control. Here are key aspects to consider for 20mm aggregates:

Gradation Types

Well-Graded

Has a good distribution of sizes within the specified limits. Produces dense concrete with good workability and strength.

Gap-Graded

Missing certain particle sizes. 20mm single-sized aggregate is intentionally gap-graded per IS:383-2016 specifications.

Uniformly-Graded

Most particles of similar size. May lead to higher voids, reduced density and increased water demand in concrete.

Common Issues & Solutions

| Issue | Potential Cause | Impact on Concrete | Solution |

|---|---|---|---|

| Excessive oversize (>25mm) | Poor crushing control or screening at quarry | Workability issues, potential for segregation | Reject batch or screen out oversized particles |

| Too much material passing 10mm | Excessive crushing or contamination with smaller sizes | Higher water and cement demand, potential strength loss | Blend with coarser material or re-screen |

| Excessive fines (<4.75mm) | Inadequate washing or crushing method issues | Higher water demand, reduced workability | Wash aggregate to remove excess fines |

| Very high fineness modulus (>8.0) | Too many coarse particles, insufficient intermediate sizes | Harsh mix, poor workability, potential voids | Blend with finer material |

| Low fineness modulus (<6.0) | Too many intermediate or fine particles | Higher water demand, potentially uneconomical mix | Add more coarse particles or screen out fines |

| Flaky or elongated particles | Poor quality control in crushing process | Reduced strength, higher water demand | Use aggregate shape correction methods |

For 20mm aggregates, the ideal fineness modulus range is 6.0 to 8.0. If your aggregate falls outside this range, it may still be usable but could require mix design adjustments. A higher fineness modulus indicates a coarser aggregate, while a lower one suggests finer particles.

Practical Applications of 20mm Aggregate

20mm coarse aggregate is one of the most widely used aggregate sizes in construction due to its versatility and cost-effectiveness:

Structural Concrete

Ideal for columns, beams, slabs, and foundations in building construction due to its strength and economy.

Pavements and Roads

Used in highway construction, pavement bases, and rigid pavements for durability and load distribution.

Hydraulic Structures

Commonly used in dams, canals, and water tanks due to its ability to produce dense, impermeable concrete.

Industrial Floors

Preferred for heavy-duty industrial floors due to good wear resistance and load-bearing capacity.

Bridge Construction

Used in bridge decks, piers, and abutments where high strength and durability are required.

Precast Elements

Used in large precast concrete elements where higher strength and economy are priorities.

The proper gradation of 20mm aggregate, as verified by sieve analysis, contributes significantly to:

- Optimal concrete mix density and strength

- Reduced cement content, leading to more economical mixes

- Improved durability and weather resistance

- Better pumpability for large concrete pours

- Reduced shrinkage cracking and thermal movement

For most structural applications, 20mm aggregate offers the optimal balance of cost and performance. It typically requires 10-15% less cement than 10mm aggregate for equivalent strength, making it the preferred choice for large volume concrete works.

Best Practices for 20mm Aggregate Testing

To ensure accurate and reliable sieve analysis results for 20mm aggregate, follow these best practices:

-

Proper Sample Collection

Never sample from just one location in the stockpile. Collect from at least three different locations and depths to ensure representativeness. For 20mm aggregate, collect a field sample of at least 25kg which can be reduced to laboratory test size.

-

Regular Equipment Calibration

Verify that sieves are not damaged or worn. Apertures in sieves can widen with use, especially for coarser sieves used for 20mm aggregate. Check calibration of balances regularly and ensure mechanical sieve shakers operate at the correct frequency.

-

Avoid Sieve Overloading

For 20mm aggregate, the mass retained on any sieve should not exceed:

- 20mm sieve: maximum 3.5 kg/329 cm²

- 10mm sieve: maximum 2.0 kg/329 cm²

- 4.75mm sieve: maximum 1.0 kg/329 cm²

Consider dividing the sample and sieving in portions if necessary. -

Consistent Sieving Duration

For mechanical sieving of 20mm aggregate, maintain a consistent duration of 15 minutes. For manual sieving, continue until less than 1% of the material passes any sieve in one minute of additional sieving.

-

Correct Sieving Motion

If sieving manually, use a combination of shaking motions:

- Side-to-side motion in various directions

- Up and down motion to allow particles to orient differently

- Circular motion to expose particles to different openings -

Weight Verification

The sum of weights retained on all sieves and the pan should be within ±0.3% of the original sample weight. Larger discrepancies indicate material loss during testing and may require retesting.

-

Regular Testing Frequency

For ongoing projects, establish a testing schedule based on material volume:

- One test per 100 cubic meters for critical structural elements

- One test per 200 cubic meters for normal construction

- Additional testing when visual inspection indicates gradation changes

Prolonged mechanical sieving (>20 minutes) can lead to particle breakdown, especially for softer aggregates. This artificially increases the percentage of finer particles and distorts test results. Limit sieving to the recommended duration.

References & Resources

For further information on sieve analysis of 20mm coarse aggregates, refer to the following standards and resources:

- IS:383-2016 - Specification for Coarse and Fine Aggregates from Natural Sources for Concrete

- IS:2386 (Part I)-1963 - Methods of Test for Aggregates for Concrete - Particle Size and Shape

- IS:2430-1986 - Methods for Sampling of Aggregates for Concrete

- ASTM C136 - Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

- BS 812: Testing Aggregates - Part 103: Methods for Determination of Particle Size Distribution

- Concrete Technology: Theory and Practice by M.S. Shetty - Chapter on Aggregates